About

What we do

Marcus Materials Co. offers engineered ceramic components to Industry and Military Suppliers Worldwide as either a direct supplier or consulting to meet your needs.

We specialize in silicon carbide and boron carbide ceramics for use in armor, semiconductor equipment, high-temperature (refractory), and wear resistance applications. We have strong technical and commercial experience with armor composites. Check out the materials that we offer, the applications we support, and our consulting activities.

Our goal

We strive to make it easy for you to work with us via effective and timely communication, with no bureaucracy nor waiting.

And the more mundane information

- Marcus Materials Co. is a C-Corporation registered in the State of Delaware in the United States of America.

- We have been in business since 1991.

- We are registered with a DUNS number, a US Government CAGE Code, and a valid SAM.gov registration eligible to accept contracts from the US government as a small business.

- Employer Identification Number (EIN), Corporate Tax ID Number is available upon request.

Materials

Engineered ceramic materials

- Aluminum Oxide (alumina, Al2O3)

- Boron Carbide (B4C), hot-pressed and reaction bonded

- Magnesium Aluminate Spinel (MgAl2O4), transparent ceramic

- Silicon Carbide (SiC), pressureless sintered and reaction bonded

- Silicon Nitride (Si3N4), pressureless sintered

Composite materials, Armor systems

- Carbon fiber / epoxy reinforcement of ceramics

- Fiberglass / epoxy reinforcement of ceramics

- Bonding of ceramic and ultrahigh molecular weight polyethylene for armor

- Aramid (Kevlar and Twaron) composites

- Transparent laminates using spinel, sapphire, AlON, glass, polycarbonate, polyurethane, and EVA

Applications

The materials that we supply are used primarily in the following applications:

- Armor

- Ballistic impact resistance

- Mining

- Pulp and paper

- Wear resistance

- High temperature applications

- Thermal management

- Nuclear power

- Corona discharge tubes

Armor

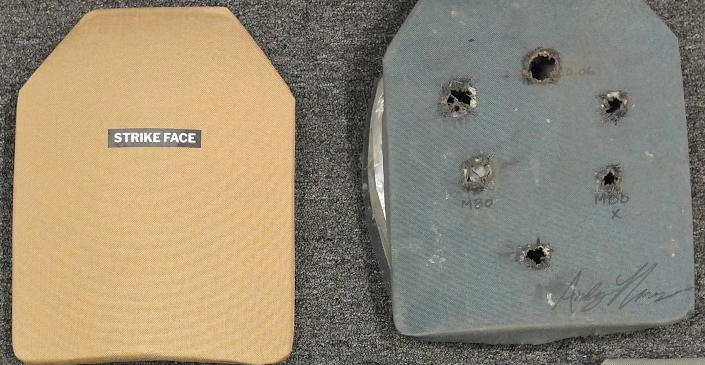

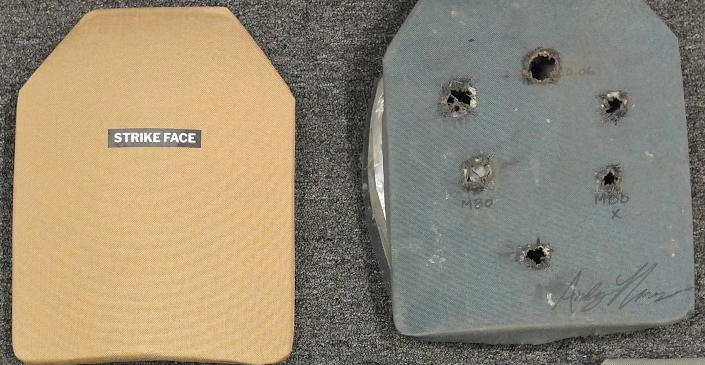

Supply and consulting of opaque and transparent armor-grade ceramics, laminates, and systems

We specialize in armor including the ceramics used as strikefaces in armor systems and the laminates that define the armor system.

We can help you choose a ceramic for a particular threat or armor specification. We can design composite laminates for you to meet a particular specification be it NIJ, STANAG, or US DoD. We can build prototype targets for you and ballistically test them.

There are not that many truly independent armor development shops. Marcus Materials Co. can support your development, prototype, testing needs, and production support needs without being a competitor. Where else can you find that kind of support?

Throw it at us - we are likely familiar with what you need to do.

Consulting

We consult on the use of engineered ceramics (application engineering), component design, supply chain, and armor composites.

Ceramic application support

Are you having difficulty determining the best engineered ceramic to use for your application, or understand the differences between the many flavors of engineered ceramics? Are you paying for hot-pressed material when reaction bonded may work as well at a much lower cost, for example? Are you having trouble with an existing supplier or have had a supply chain disruption? We have been doing this for a long time and know our way around engineered ceramic materials and the ceramic industry. We do our best to advise our customers on the best material for the job, even if that means recommending a material that we do not supply. To that end, we regularly consult to assist in material selection, test/evaluation of engineered ceramic materials, and supply-chain issues.

Armor composites support

We have been involved with armor composites since 1987. Most composites we work with include a ceramic component. We can laminate targets for you, design laminates for specific threats, multihit, or other program-specific requirements, and ballistically test targets. The composites we focus on incorporate ceramic strikefaces to defeat threats including 5.56mm, 7.62 AP, up to 14.5mm.

We work hard to make it easy for you to work with us. You will experience effective and timely communication with no bureaucracy nor waiting. Give us a call to discuss your needs.

Privacy Policy

Marcus Materials Co. respects your privacy rights. Any information sent to us via this website will be kept strictly confidential and will only be used to respond to your inquiry to us. Marcus Materials Co. will not distribute, sell, rent, loan, trade, or lease the information you have submitted to us to any third party. We will use care in protecting the privacy and security of your information.

We request that you do not send any sensitive or proprietary information to us without prior accommodations so that we can setup proper archival and working boundaries around the information for your protection.

Marcus Materials Co. cannot be responsible for any unsolicited sensitive or proprietary information sent to us via this website.

Information shared outside of the inquiry submission mechanism on this website is not covered under this Privacy Statement. Such information may be covered under separate Non-Disclosure Agreement if mutually deemed necessary. A copy of Marcus Materials Co. standard Mutual Non-Disclosure Agreement can be found under the Downloads section of this website.

Any questions or comments pertaining to this privacy statement should be directed to the primary commercial contact listed on the Contact Us section of this website.

Guiding Principles

Each member of the Marcus Materials Co. team shall promote and preserve the ideals of fairness, honor, integrity, and respect in all dealings. Equity and balance is to be achieved and maintained in all relationships. We shall encourage cooperation and recognize that cooperation is sometimes hidden behind competition, ego, and emotion. We shall stay clear of inward focus. We shall be both diligent and patient in our endeavors. We shall not take advantage of people or situations nor unfairly or unduly capitalize at the expense of others. We shall not expect nor accept any more or less than what has been earned and is deserved. We shall coexist in harmony with nature, our environment, and society. We believe that our customers and suppliers expect quality service and quality product and it is our duty to deliver both.

The Marcus Materials Co. team believes that when profit becomes our primary focus our Guiding Principles will have been compromised. We believe that long-term relationships and profits will be realized as a result of our internalizing and practicing our Guiding Principles.

Frequently Asked Questions

QUESTION:

Does Marcus Materials Co. supply ceramic powder or raw materials?

ANSWER:

No. We only supply components made from those materials listed under the “Materials” section.

QUESTION:

Does Marcus Materials Co. supply any parts from stock?

ANSWER:

We do stock some standard sizes of flat tiles and curved body armor tiles in SiC and B4C; however, most components we supply are made to customer specifications. We usually maintain a variety of thicknesses of body armor tiles for customer testing and development.

QUESTION:

Does Marcus Materials Co. accept credit cards?

ANSWER:

We do not directly accept credit cards; however, we can accept credit card payments via PayPal.com. Please contact us for more information about making a payment using PayPal.com.

Tools

Conversion of Units commonly used in armor calculations

Calculate the weight of a hexagonal tile

Calculate the weight and areal density of a rectangular or square tile.

Show list of densities (g/cc) of many materials.

Hex tile calculations

F = Dimension from flat-to-flat

S = length of side = ((F/2)/0.866)

Area = 2.598*S*S

Imperial Units (except for density)

(calculations are run when you leave the $/lb fields)

Metric Units

(calculations are run when you leave the $/kg field)

Armor Unit Conversions

Enter numbers in any text box and press the tab key to

initiate the calculation for the corresponding unit conversion.

Volume

1 cc = 0.06102376 in³

1 in³ = 16.38706 cc

1 in³ = 5.78704E-04 ft³

1 ft³ = 1728 in³

1 ft³ = 28316.85 cc

1 ft³ = 0.02831685 m³

Hex Tile Calculations:

R = from center to flat edge

S = length of side

R = 0.866*S

2R = Flat-to-Flat

Area = 3.464*R*R

Area = 2.598*S*S

Calculate Weight of tile

Densities of materials

Click on column header to sort.

| CATEGORY ↕ |

MATERIAL ↕ |

DENSITY (g/cc) ↕ |

| Ceramic | Alanx CG896 | 3.32 |

| Ceramic | Alumina | 3.9 |

| Ceramic | Alumina, 85% | 3.41 |

| Ceramic | Alumina, 90% | 3.6 |

| Ceramic | Alumina, 94% | 3.7 |

| Ceramic | Alumina, 96% | 3.75 |

| Ceramic | Alumina, 99% | 3.9 |

| Ceramic | Alumina, 99.5% | 3.89 |

| Ceramic | Alumina, 99.9% | 3.96 |

| Ceramic | Aluminosilicate | 2.6 |

| Ceramic | Aluminum Nitride | 3.25 |

| Ceramic | BeO | 2.85 |

| Ceramic | Boron Carbide | 2.5 |

| Ceramic | Borosilicate Glass | 2.3 |

| Ceramic | Glass | 2.6 |

| Ceramic | Graphite | 2.163 |

| Ceramic | Hafnium Carbide | 12.76 |

| Ceramic | Iron Slag | 2.755 |

| Ceramic | Lead Glass | 2.8 |

| Ceramic | Mg-PSZ | 5.75 |

| Ceramic | Mullite | 2.82 |

| Ceramic | Nitride-Bonded SiC | 2.54 |

| Ceramic | PSZ | 5.75 |

| Ceramic | Quartz Glass | 2.2 |

| Ceramic | RB-SiC | 3.09 |

| Ceramic | Refrax | 2.54 |

| Ceramic | SNBSN / "Refrax" | 2.54 |

| Ceramic | Sapphire | 3.99 |

| Ceramic | SiAlON | 3.3 |

| Ceramic | Silicon Nitride | 3.28 |

| Ceramic | Silicon carbide | 3.2 |

| Ceramic | Sintered SiC | 3.1 |

| Ceramic | TiC | 4.94 |

| Ceramic | Tungsten Carbide | 15.7 |

| Ceramic | Vanadium Carbide | 5.71 |

| Ceramic | WC / Tungsten Carbide | 15.7 |

| Ceramic | Y-TZP | 6.1 |

| Ceramic | ZTA | 4.1 |

| Ceramic | Zirconia | 5.75 |

| Ceramic | Zirconium Carbide | 6.56 |

| Chemical | Benzene | 0.737 |

| Chemical | Gasoline | 0.721 |

| Composite | Carbon-Carbon Composite | 1.65 |

| Liquid | Ethyl Alcohol | 0.802 |

| Liquid | Methyl Alcohol | 0.809 |

| Liquid | Mineral Oil | 0.914 |

| Liquid | Seawater | 1.025 |

| Liquid | Vegetable Oil | 0.93 |

| Liquid | Water, 100 °C | 0.9581 |

| Liquid | Water, 4 °C | 0.99997 |

| Liquid | Water, Ice | 0.897 |

| Liquid | Water, Seawater | 1.025 |

| Metal | Aluminum | 2.643 |

| Metal | Aluminum bronze | 7.702 |

| Metal | Aluminum, 2024-T3 | 2.77 |

| Metal | Aluminum, 6061-T6 | 2.7 |

| Metal | Aluminum, 7079-T6 | 2.74 |

| Metal | Beryllium | 1.8477 |

| Metal | Beryllium, QMV | 1.85 |

| Metal | Brass | 8.553 |

| Metal | Bronze, aluminum | 7.702 |

| Metal | Bronze, phosphor | 8.8 |

| Metal | Bronze, ~11% Tin | 8.1 |

| Metal | Carbon Steel | 7.84 |

| Metal | Carbon Tool Steel | 7.82 |

| Metal | Cobalt | 8.8 |

| Metal | Copper, Pure | 8.9 |

| Metal | Copper, cast-rolled | 8.906 |

| Metal | German Silver | 8.586 |

| Metal | Gold Coin (US) | 17.19 |

| Metal | Gold, Pure | 19.32 |

| Metal | Gold, cast-hammered | 19.3 |

| Metal | High Speed Tool Steel | 8.75 |

| Metal | Iridium | 22.16 |

| Metal | Iron, Cast, Pig | 7.207 |

| Metal | Iron, Ferrosilicon | 6.984 |

| Metal | Iron, Spiegeleisen | 7.496 |

| Metal | Iron, grey cast | 7.079 |

| Metal | Iron, wrought | 7.658 |

| Metal | Lead | 11.37 |

| Metal | Magnesium, Pure | 1.7 |

| Metal | Manganese | 7.608 |

| Metal | Mercury | 13.57 |

| Metal | Molybdenum, wrought | 10.3 |

| Metal | Monel Metal, rolled | 8.688 |

| Metal | Nickel | 8.602 |

| Metal | Nickel, Pure | 8.9 |

| Metal | Pig Iron | 7.207 |

| Metal | Platinum | 21.3 |

| Metal | Plutonium, alpha phase | 19.35 |

| Metal | Pure Iron | 7.86 |

| Metal | Silver, Cast-hammered | 10.51 |

| Metal | Silver, Pure | 10.5 |

| Metal | Soft Steel (0.06% C) | 7.87 |

| Metal | Stainless 18Cr-8Ni | 8.03 |

| Metal | Stainless 27Cr | 7.47 |

| Metal | Stainless Steel, 304 | 8.03 |

| Metal | Steel, C1020, HR | 7.85 |

| Metal | Steel, cold-drawn | 7.83 |

| Metal | Steel, tool | 7.715 |

| Metal | Tantalum | 16.6 |

| Metal | Thorium, Ind. melted | 11.6 |

| Metal | Tin, cast-hammered | 7.352 |

| Metal | Titanium | 4.5 |

| Metal | Titanium, B 120VCA | 4.85 |

| Metal | Tungsten | 18.82 |

| Metal | Uranium | 18.74 |

| Metal | Uranium D38 | 18.97 |

| Metal | Wrought Iron | 7.75 |

| Metal | Zinc, Cast | 7.049 |

| Metal | Zirconium | 6.3798 |

| Mineral | Coal, Anthracite | 1.554 |

| Mineral | Coal, Bituminous | 1.346 |

| Mineral | Coal, Coke | 1.201 |

| Mineral | Coal, Lignite | 1.25 |

| Mineral | Copper Ore, pyrites | 4.197 |

| Mineral | Corundum-Crystal Form | 3.99 |

| Mineral | Iron Ore, Hematite | 5.206 |

| Mineral | Iron Ore, Limonite | 3.796 |

| Mineral | Iron Ore, Magnetite | 5.046 |

| Mineral | Lead Ore, Galena | 7.449 |

| Mineral | Manganese Ore | 4.149 |

| Mineral | Pyrolusite, Mn Ore | 4.149 |

| Mineral | Tin Ore, cassiterite | 6.695 |

| Mineral | Zinc Ore, blende | 4.052 |

| Other | Ice | 0.897 |

| Other | Leather, common | 0.945 |

| Other | Paper | 0.929 |

| Other | Paraffin | 0.898 |

| Plastic | HDPE | 0.955 |

| Plastic | Kevlar 149 | 1.47 |

| Plastic | Kevlar 29 | 1.44 |

| Plastic | Kevlar 49 | 1.44 |

| Plastic | Polyurethane | 1.0 |

| Plastic | Rubber | 1.506 |

| Wood | Birch | 0.705 |

| Wood | Cherry | 0.433 |

| Wood | Mahogony | 0.705 |

| Wood | Red Oak | 0.673 |

| Wood | Southern Pine | 0.65 |

| Wood | Sugar Maple | 0.689 |

| Wood | Walnut | 0.593 |

The data below is the same as above but in

ASCII format in-case you want to copy it.

Densities sorted by Material Category

Category Material Density (g/cc)

-------- --------------- --------------

Ceramic Alanx CG896 3.32

Ceramic Alumina 3.9

Ceramic Alumina, 85% 3.41

Ceramic Alumina, 90% 3.6

Ceramic Alumina, 94% 3.7

Ceramic Alumina, 96% 3.75

Ceramic Alumina, 99% 3.9

Ceramic Alumina, 99.5% 3.89

Ceramic Alumina, 99.9% 3.96

Ceramic Aluminosilicate 2.6

Ceramic Aluminum Nitride 3.25

Ceramic BeO 2.85

Ceramic Boron Carbide 2.5

Ceramic Borosilicate Glass 2.3

Ceramic Glass 2.6

Ceramic Graphite 2.163

Ceramic Hafnium Carbide 12.76

Ceramic Iron Slag 2.755

Ceramic Lead Glass 2.8

Ceramic Mg-PSZ 5.75

Ceramic Mullite 2.82

Ceramic Nitride-Bonded SiC 2.54

Ceramic PSZ 5.75

Ceramic Quartz Glass 2.2

Ceramic RB-SiC 3.09

Ceramic Refrax 2.54

Ceramic SNBSN / "Refrax" 2.54

Ceramic Sapphire 3.99

Ceramic SiAlON 3.3

Ceramic Silicon Nitride 3.28

Ceramic Silicon carbide 3.2

Ceramic Sintered SiC 3.1

Ceramic TiC 4.94

Ceramic Tungsten Carbide 15.7

Ceramic Vanadium Carbide 5.71

Ceramic WC / Tungsten Carbide 15.7

Ceramic Y-TZP 6.1

Ceramic ZTA 4.1

Ceramic Zirconia 5.75

Ceramic Zirconium Carbide 6.56

Chemical Benzene 0.737

Chemical Gasoline 0.721

Composite Carbon-Carbon Composite 1.65

Liquid Ethyl Alcohol 0.802

Liquid Methyl Alcohol 0.809

Liquid Mineral Oil 0.914

Liquid Seawater 1.025

Liquid Vegetable Oil 0.93

Liquid Water, 100 °C 0.9581

Liquid Water, 4 °C 0.99997

Liquid Water, Ice 0.897

Liquid Water, Seawater 1.025

Metal Aluminum 2.643

Metal Aluminum bronze 7.702

Metal Aluminum, 2024-T3 2.77

Metal Aluminum, 6061-T6 2.7

Metal Aluminum, 7079-T6 2.74

Metal Beryllium 1.8477

Metal Beryllium, QMV 1.85

Metal Brass 8.553

Metal Bronze, aluminum 7.702

Metal Bronze, phosphor 8.8

Metal Bronze, ~11% Tin 8.1

Metal Carbon Steel 7.84

Metal Carbon Tool Steel 7.82

Metal Cobalt 8.8

Metal Copper, Pure 8.9

Metal Copper, cast-rolled 8.906

Metal German Silver 8.586

Metal Gold Coin (US) 17.19

Metal Gold, Pure 19.32

Metal Gold, cast-hammered 19.3

Metal High Speed Tool Steel 8.75

Metal Iridium 22.16

Metal Iron, Cast, Pig 7.207

Metal Iron, Ferrosilicon 6.984

Metal Iron, Spiegeleisen 7.496

Metal Iron, grey cast 7.079

Metal Iron, wrought 7.658

Metal Lead 11.37

Metal Magnesium, Pure 1.7

Metal Manganese 7.608

Metal Mercury 13.57

Metal Molybdenum, wrought 10.3

Metal Monel Metal, rolled 8.688

Metal Nickel 8.602

Metal Nickel, Pure 8.9

Metal Pig Iron 7.207

Metal Platinum 21.3

Metal Plutonium, alpha phase 19.35

Metal Pure Iron 7.86

Metal Silver, Cast-hammered 10.51

Metal Silver, Pure 10.5

Metal Soft Steel (0.06% C) 7.87

Metal Stainless 18Cr-8Ni 8.03

Metal Stainless 27Cr 7.47

Metal Stainless Steel, 304 8.03

Metal Steel, C1020, HR 7.85

Metal Steel, cold-drawn 7.83

Metal Steel, tool 7.715

Metal Tantalum 16.6

Metal Thorium, Ind. melted 11.6

Metal Tin, cast-hammered 7.352

Metal Titanium 4.5

Metal Titanium, B 120VCA 4.85

Metal Tungsten 18.82

Metal Uranium 18.74

Metal Uranium D38 18.97

Metal Wrought Iron 7.75

Metal Zinc, Cast 7.049

Metal Zirconium 6.3798

Mineral Coal, Anthracite 1.554

Mineral Coal, Bituminous 1.346

Mineral Coal, Coke 1.201

Mineral Coal, Lignite 1.25

Mineral Copper Ore, pyrites 4.197

Mineral Corundum-Crystal Form 3.99

Mineral Iron Ore, Hematite 5.206

Mineral Iron Ore, Limonite 3.796

Mineral Iron Ore, Magnetite 5.046

Mineral Lead Ore, Galena 7.449

Mineral Manganese Ore 4.149

Mineral Pyrolusite, Mn Ore 4.149

Mineral Tin Ore, cassiterite 6.695

Mineral Zinc Ore, blende 4.052

Other Ice 0.897

Other Leather, common 0.945

Other Paper 0.929

Other Paraffin 0.898

Plastic HDPE 0.955

Plastic Kevlar 149 1.47

Plastic Kevlar 29 1.44

Plastic Kevlar 49 1.44

Plastic Polyurethane 1

Plastic Rubber 1.506

Wood Birch 0.705

Wood Cherry 0.433

Wood Mahogony 0.705

Wood Red Oak 0.673

Wood Southern Pine 0.65

Wood Sugar Maple 0.689

Wood Walnut 0.593

Densities sorted by Material Density

Category Material Density (g/cc)

-------- --------------- --------------

Wood Cherry 0.433

Wood Walnut 0.593

Wood Southern Pine 0.65

Wood Red Oak 0.673

Wood Sugar Maple 0.689

Wood Birch 0.705

Wood Mahogony 0.705

Chemical Gasoline 0.721

Chemical Benzene 0.737

Liquid Ethyl Alcohol 0.802

Liquid Methyl Alcohol 0.809

Other Ice 0.897

Liquid Water, Ice 0.897

Other Paraffin 0.898

Liquid Mineral Oil 0.914

Other Paper 0.929

Liquid Vegetable Oil 0.93

Other Leather, common 0.945

Plastic HDPE 0.955

Liquid Water, 100 °C 0.9581

Liquid Water, 4 °C 0.99997

Plastic Polyurethane 1

Liquid Seawater 1.025

Liquid Water, Seawater 1.025

Mineral Coal, Coke 1.201

Mineral Coal, Lignite 1.25

Mineral Coal, Bituminous 1.346

Plastic Kevlar 29 1.44

Plastic Kevlar 49 1.44

Plastic Kevlar 149 1.47

Plastic Rubber 1.506

Mineral Coal, Anthracite 1.554

Composite Carbon-Carbon Composite 1.65

Metal Magnesium, Pure 1.7

Metal Beryllium 1.8477

Metal Beryllium, QMV 1.85

Ceramic Graphite 2.163

Ceramic Quartz Glass 2.2

Ceramic Borosilicate Glass 2.3

Ceramic Boron Carbide 2.5

Ceramic Nitride-Bonded SiC 2.54

Ceramic Refrax 2.54

Ceramic SNBSN / "Refrax" 2.54

Ceramic Aluminosilicate 2.6

Ceramic Glass 2.6

Metal Aluminum 2.643

Metal Aluminum, 6061-T6 2.7

Metal Aluminum, 7079-T6 2.74

Ceramic Iron Slag 2.755

Metal Aluminum, 2024-T3 2.77

Ceramic Lead Glass 2.8

Ceramic Mullite 2.82

Ceramic BeO 2.85

Ceramic RB-SiC 3.09

Ceramic Sintered SiC 3.1

Ceramic Silicon carbide 3.2

Ceramic Aluminum Nitride 3.25

Ceramic Silicon Nitride 3.28

Ceramic SiAlON 3.3

Ceramic Alanx CG896 3.32

Ceramic Alumina, 85% 3.41

Ceramic Alumina, 90% 3.6

Ceramic Alumina, 94% 3.7

Ceramic Alumina, 96% 3.75

Mineral Iron Ore, Limonite 3.796

Ceramic Alumina, 99.5% 3.89

Ceramic Alumina 3.9

Ceramic Alumina, 99% 3.9

Ceramic Alumina, 99.9% 3.96

Mineral Corundum-Crystal Form 3.99

Ceramic Sapphire 3.99

Mineral Zinc Ore, blende 4.052

Ceramic ZTA 4.1

Mineral Manganese Ore 4.149

Mineral Pyrolusite, Mn Ore 4.149

Mineral Copper Ore, pyrites 4.197

Metal Titanium 4.5

Metal Titanium, B 120VCA 4.85

Ceramic TiC 4.94

Mineral Iron Ore, Magnetite 5.046

Mineral Iron Ore, Hematite 5.206

Ceramic Vanadium Carbide 5.71

Ceramic Mg-PSZ 5.75

Ceramic PSZ 5.75

Ceramic Zirconia 5.75

Ceramic Y-TZP 6.1

Metal Zirconium 6.3798

Ceramic Zirconium Carbide 6.56

Mineral Tin Ore, cassiterite 6.695

Metal Iron, Ferrosilicon 6.984

Metal Zinc, Cast 7.049

Metal Iron, grey cast 7.079

Metal Iron, Cast, Pig 7.207

Metal Pig Iron 7.207

Metal Tin, cast-hammered 7.352

Mineral Lead Ore, Galena 7.449

Metal Stainless 27Cr 7.47

Metal Iron, Spiegeleisen 7.496

Metal Manganese 7.608

Metal Iron, wrought 7.658

Metal Aluminum bronze 7.702

Metal Bronze, aluminum 7.702

Metal Steel, tool 7.715

Metal Wrought Iron 7.75

Metal Carbon Tool Steel 7.82

Metal Steel, cold-drawn 7.83

Metal Carbon Steel 7.84

Metal Steel, C1020, HR 7.85

Metal Pure Iron 7.86

Metal Soft Steel (0.06% C) 7.87

Metal Stainless 18Cr-8Ni 8.03

Metal Stainless Steel, 304 8.03

Metal Bronze, ~11% Tin 8.1

Metal Brass 8.553

Metal German Silver 8.586

Metal Nickel 8.602

Metal Monel Metal, rolled 8.688

Metal High Speed Tool Steel 8.75

Metal Bronze, phosphor 8.8

Metal Cobalt 8.8

Metal Copper, Pure 8.9

Metal Nickel, Pure 8.9

Metal Copper, cast-rolled 8.906

Metal Molybdenum, wrought 10.3

Metal Silver, Pure 10.5

Metal Silver, Cast-hammered 10.51

Metal Lead 11.37

Metal Thorium, Ind. melted 11.6

Ceramic Hafnium Carbide 12.76

Metal Mercury 13.57

Ceramic Tungsten Carbide 15.7

Ceramic WC / Tungsten Carbide 15.7

Metal Tantalum 16.6

Metal Gold Coin (US) 17.19

Metal Uranium 18.74

Metal Tungsten 18.82

Metal Uranium D38 18.97

Metal Gold, cast-hammered 19.3

Metal Gold, Pure 19.32

Metal Plutonium, alpha phase 19.35

Metal Platinum 21.3

Metal Iridium 22.16

Contact

The following email address is not a clickable link. You'll need to type it into your email system. Sorry, you cannot copy and paste it. It will not paste correctly. This is to try to prevent bots from harvesting the email address and bombarding us with spam.

Email

moc.nullslairetaMsucraMnull@yriuqni

Phone

91null57-13null7-20null3 1+

Elements

Text

This is bold and this is strong. This is italic and this is emphasized.

This is superscript text and this is subscript text.

This is underlined and this is code: for (;;) { ... }. Finally, this is a link.

Heading Level 2

Heading Level 3

Heading Level 4

Heading Level 5

Heading Level 6

Blockquote

Fringilla nisl. Donec accumsan interdum nisi, quis tincidunt felis sagittis eget tempus euismod. Vestibulum ante ipsum primis in faucibus vestibulum. Blandit adipiscing eu felis iaculis volutpat ac adipiscing accumsan faucibus. Vestibulum ante ipsum primis in faucibus lorem ipsum dolor sit amet nullam adipiscing eu felis.

Preformatted

i = 0;

while (!deck.isInOrder()) {

print 'Iteration ' + i;

deck.shuffle();

i++;

}

print 'It took ' + i + ' iterations to sort the deck.';

Lists

Unordered

- Dolor pulvinar etiam.

- Sagittis adipiscing.

- Felis enim feugiat.

Alternate

- Dolor pulvinar etiam.

- Sagittis adipiscing.

- Felis enim feugiat.

Ordered

- Dolor pulvinar etiam.

- Etiam vel felis viverra.

- Felis enim feugiat.

- Dolor pulvinar etiam.

- Etiam vel felis lorem.

- Felis enim et feugiat.

Icons

Actions

Table

Default

| Name |

Description |

Price |

| Item One |

Ante turpis integer aliquet porttitor. |

29.99 |

| Item Two |

Vis ac commodo adipiscing arcu aliquet. |

19.99 |

| Item Three |

Morbi faucibus arcu accumsan lorem. |

29.99 |

| Item Four |

Vitae integer tempus condimentum. |

19.99 |

| Item Five |

Ante turpis integer aliquet porttitor. |

29.99 |

|

100.00 |

Alternate

| Name |

Description |

Price |

| Item One |

Ante turpis integer aliquet porttitor. |

29.99 |

| Item Two |

Vis ac commodo adipiscing arcu aliquet. |

19.99 |

| Item Three |

Morbi faucibus arcu accumsan lorem. |

29.99 |

| Item Four |

Vitae integer tempus condimentum. |

19.99 |

| Item Five |

Ante turpis integer aliquet porttitor. |

29.99 |

|

100.00 |